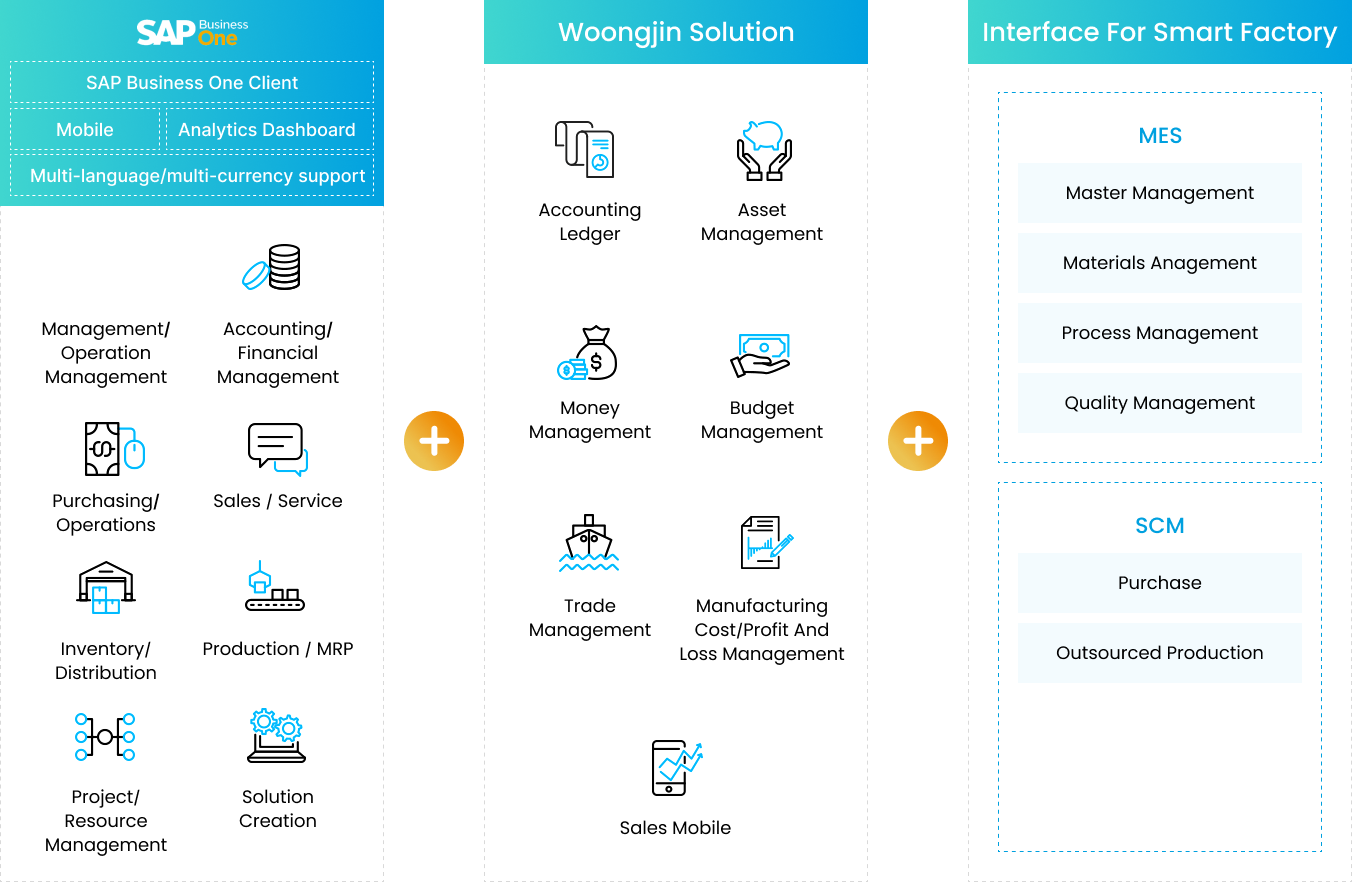

Manufacturing innovation based on SAP Business One

SMART FACTORY

Woongjin is carrying out a smart factory construction project.

Afterwards, we support the stable establishment of the system through professional maintenance.

With SAP core and add-on functions, SAP advancement can be carried out step by step according to field needs.

Smart factory

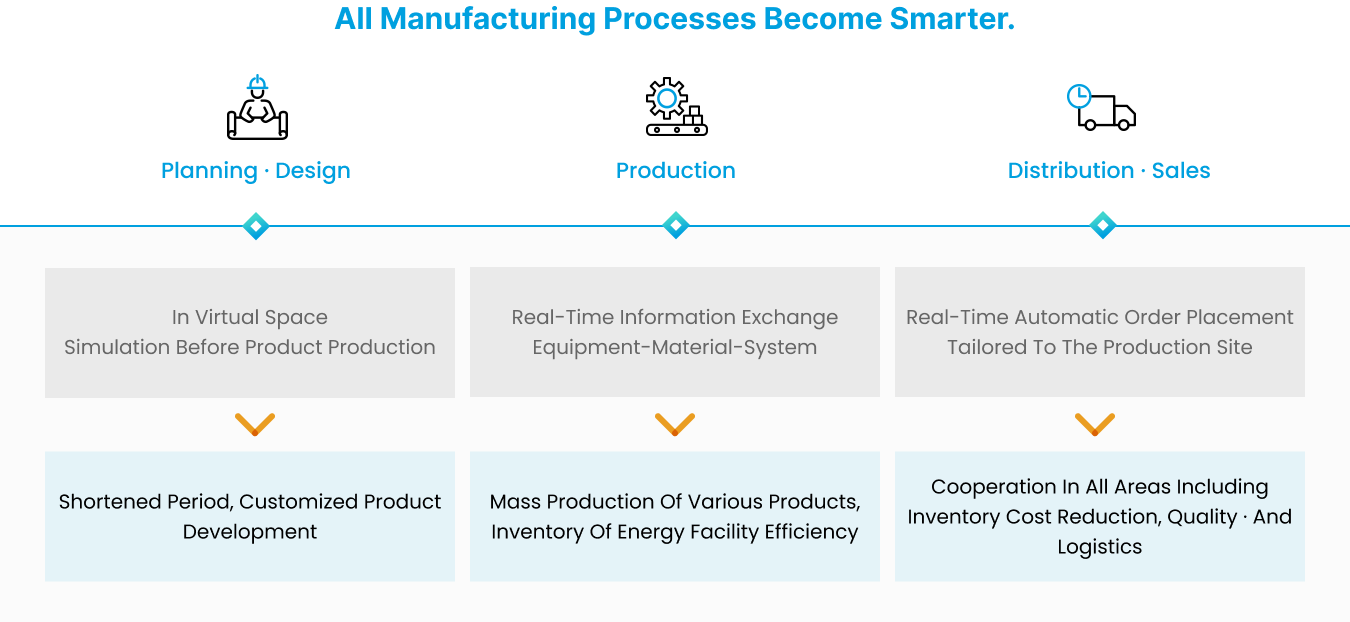

A smart factory is a technologically advanced and human-centered manufacturing facility that leverages Information and Communication Technology (ICT) to seamlessly integrate all production processes, from product planning to sales. The primary goal of a smart factory is to efficiently produce customized products with minimal cost and time, thus optimizing the manufacturing process.

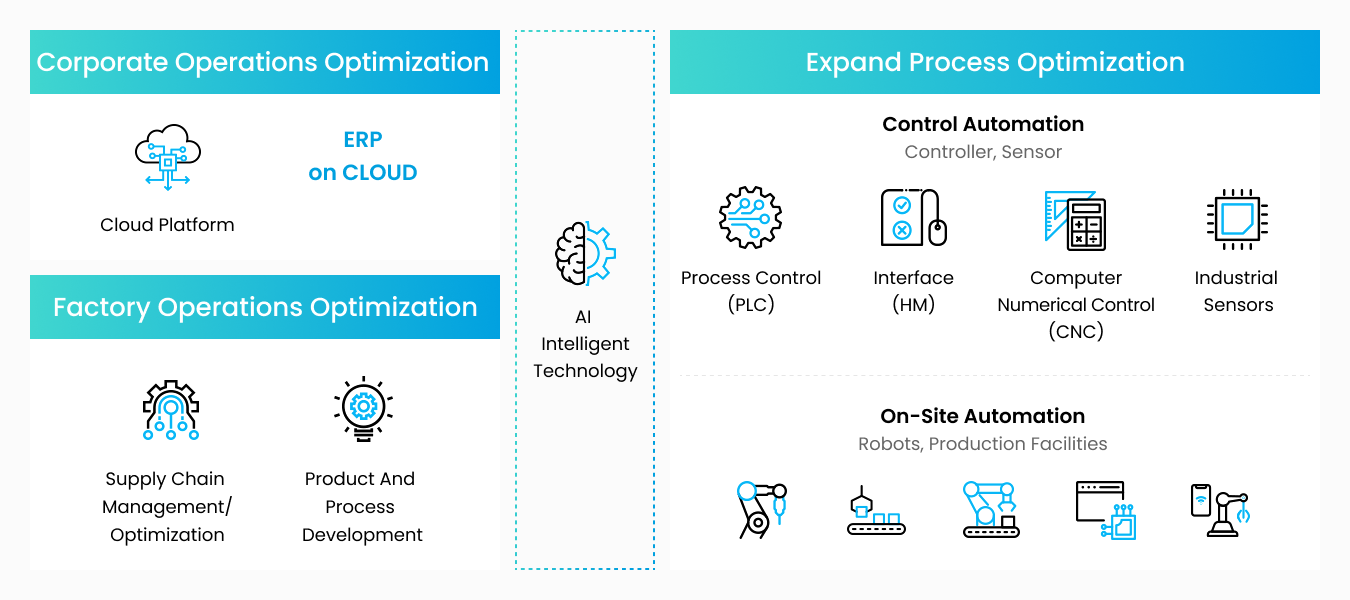

The basis of a smart factory is ERP.

A smart factory entails more than simply rearranging facilities for human convenience, such as altering production lines or processes.

Its objective is to comprehend the entire factory's process flow, quantify it, transform it into meaningful data, and optimize the expansion process towards on-site automation and control automation.

At this juncture, what's essential is for ERP to become the standard across the entire process. Implementing ERP serves as the initial step towards establishing a smart factory.

Connecting smart factories for manufacturing innovation

A smart factory needs to accurately capture the data flow taking place at the manufacturing site, facilitated by ERP. By integrating various solutions essential for a smart factory, the company can realize its vision of a smart factory and embark on the first step towards manufacturing innovation.

Woongjin paves the way for a seamless transition towards a perfected smart factory, connecting the future of manufacturing.

Step-by-step construction possible according to company size

The smart factory support stage enables the selection of the appropriate level and functionality based on the company's circumstances, facilitating gradual implementation accordingly.

We are establishing a foundation that enables small and medium-sized businesses to easily commence operations at a relatively low cost, and we are pleased with the results that have surpassed our expectations. Even at the basic level of a smart factory, real-time production tracking and management of products are feasible, and even material history management (lot-tracking) is attainable.

| division | On-site automation | Factory operation | Corporate resource management | product development | Supply chain management | |

|---|---|---|---|---|---|---|

| 2nd stage of advancement | Altitude | IoT/IoS-based CPS | Business CPS network collaboration in Internet space |

|||

| IoT/IoSization | IoT/IoS (modularization), big data-based diagnosis and operation | |||||

| middle 2 | Facility control automation | Real-time factory control | Factory operation integration | Simulation and batch process automation |

Collaboration on multi-product development | |

| 1st stage of advancement | middle 1 | Automatic collection of equipment data | Real-time decision making | Cross-functional integration | Automate and collaborate on technical information creation | Collaboration on multi-product production |

| basic level | basic | Performance aggregation automation | Process Logistics Management (POP) | Individual operation of management function-oriented functions | Technology/delivery management through server | Reliance on a single parent company |

From smart factory to intelligent factory

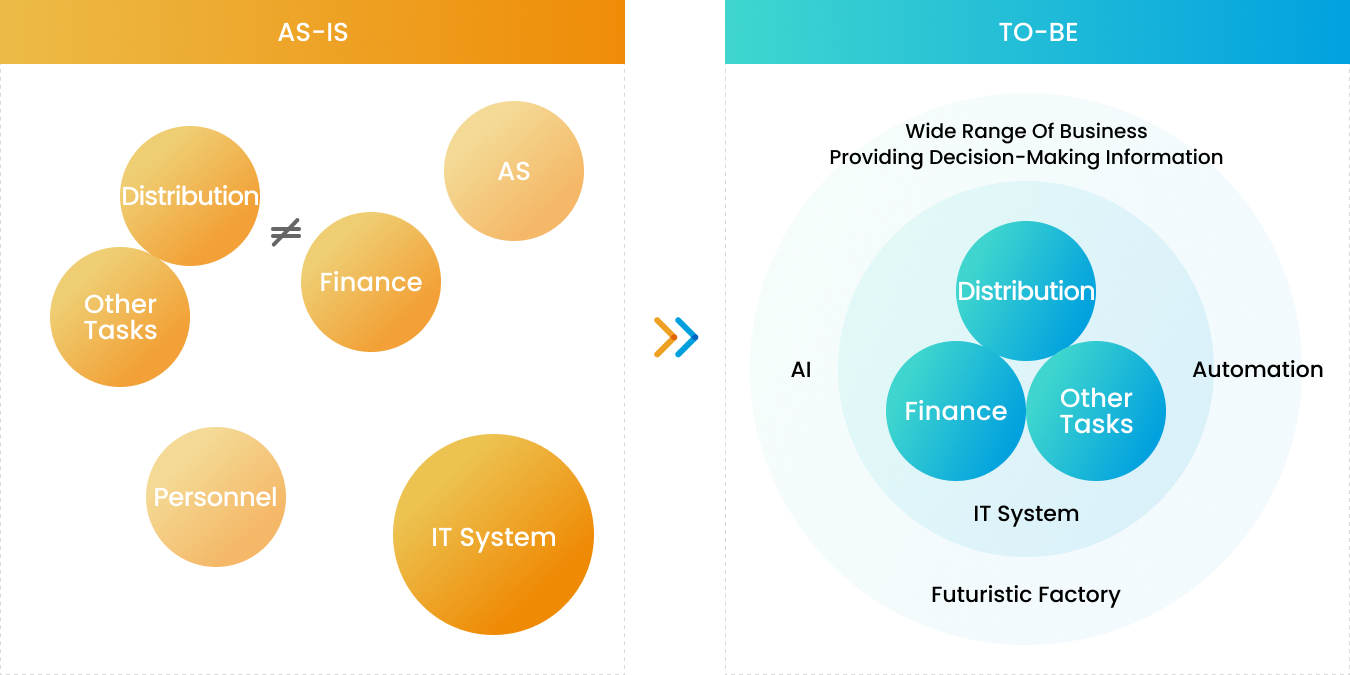

(1) Introduction of Standardized Systems

The implementation of ERP for smart factories will significantly alter the company's management information system environment from its current state.

A smart ERP system should have the capability to influence top-level decision-making.

It's crucial to integrate disparate tasks and organize data according to predefined rules and standards.

This advancement brings us closer to the ultra-intelligent factories of the future.

(2) Changes in Smart Factory Operations

The integration of logistics and financial data is anticipated to streamline management processes, thereby enhancing operational efficiency and bolstering production competitiveness while achieving greater work standardization.

Additionally, this integrated data contributes to informed decision-making at the top level of the organization. Ultimately, these advancements lay the foundation for innovation, facilitating the expansion of new business opportunities.

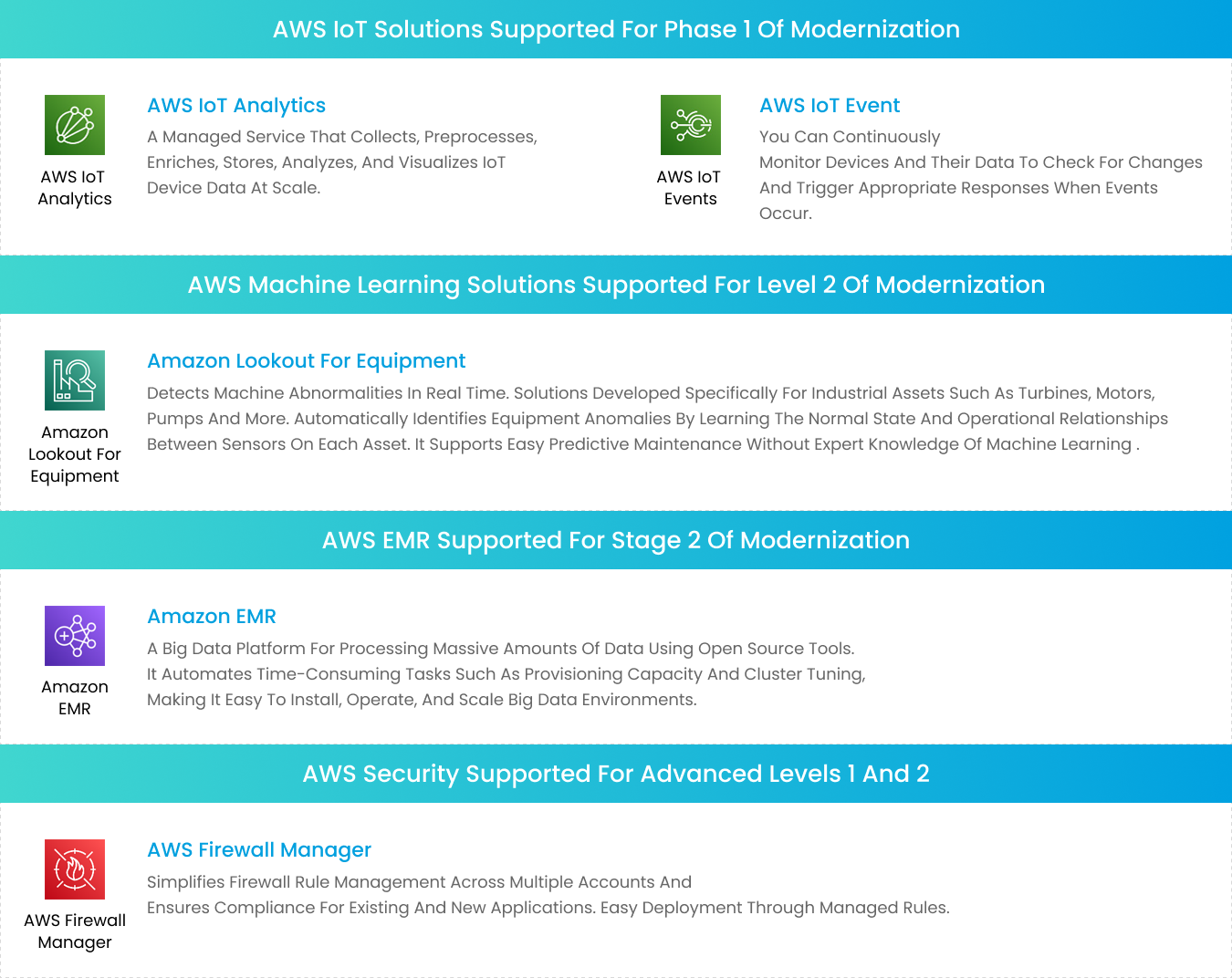

Smart Factory on AWS

Integrating Amazon Web Services (AWS) into your smart factory operations enables smarter functionality.

By doing so, the envisioned smart factory becomes a reality, marking the initial stride toward manufacturing innovation.

Woongjin paves the way for a flawless smart factory, connecting you to the future of manufacturing excellence.

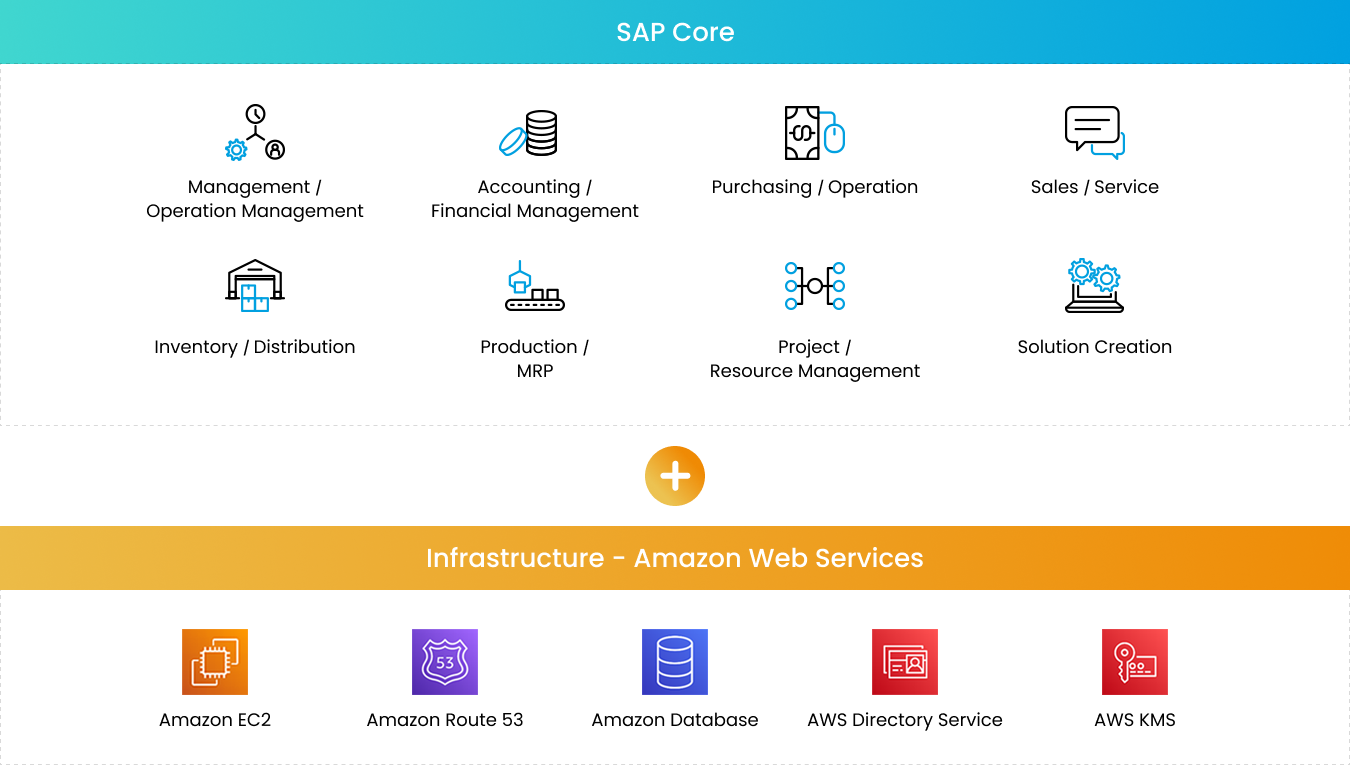

basic level

SAP Business One on AWS

As an initial step towards implementing a smart factory, SAP Business One ERP is deployed on AWS.

This integration facilitates the digitization of analog production data within the factory, enabling effective management of product production history.

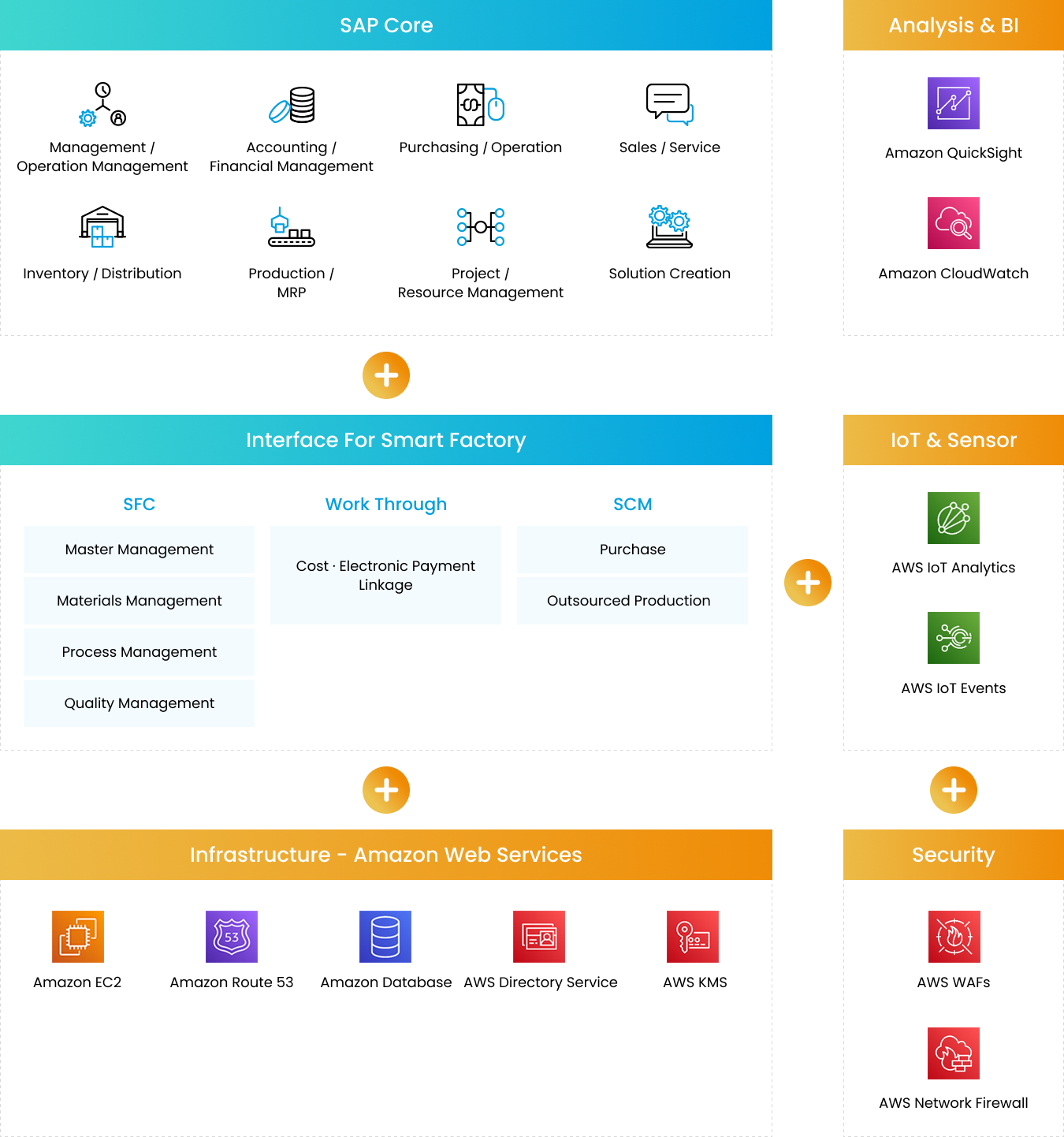

1st stage of advancement

ERP & SFC on AWS + IoT devices

During this stage, production information is gathered and analyzed in real-time.

SAP Business One ERP and SFC (Shop Floor Control) are both operated on AWS, with additional data being collected via barcodes.

This collected production data can then be analyzed for quality and incorporated into production planning and decision-making processes.

Simultaneously, the collected data undergoes analysis, with the information being visualized through AWS QuickSight.

Moreover, device and data monitoring is continuously conducted through AWS IoT Events to detect any changes. When an event occurs, appropriate responses can be triggered accordingly.

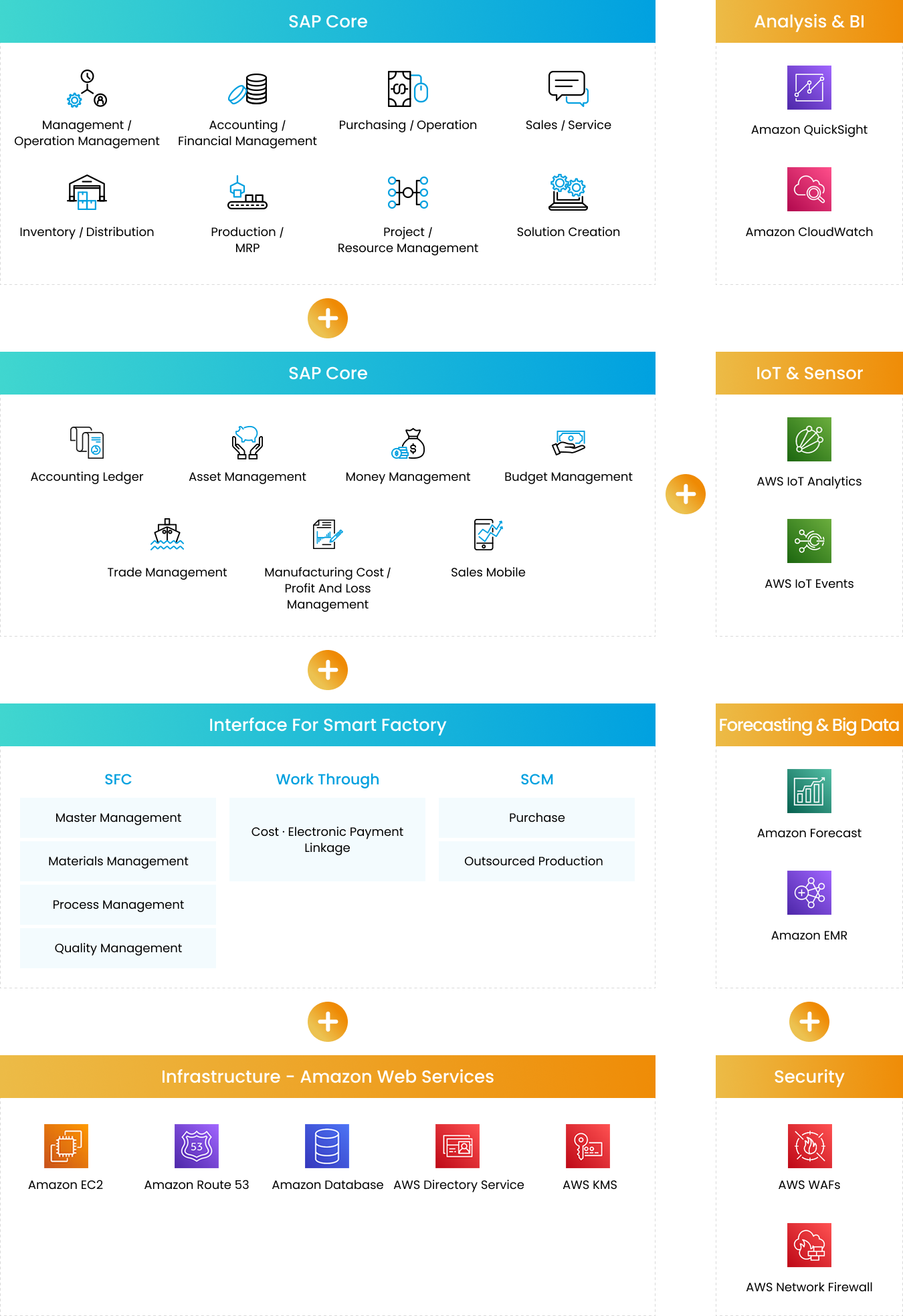

2nd stage of advancement

ERP & SFC on AWS + IoT device + AWS analysis

SAP Business One ERP and SFC (Shop Floor Control) are hosted on AWS, facilitating real-time control through the collection and analysis of production data.

Supplementary information is acquired through barcode scanning.

Moreover, the collected data is visually represented using AWS QuickSight.

Furthermore, by integrating AWS IoT solutions customized for each factory's needs, we establish and forecast intelligent factories with optimized real-time control and production processes.

Amazon Lookout for Equipment is utilized to detect abnormal machine behavior using existing industrial sensor data.

Here are AWS-supported solutions that can be applied step by step